To Label, or Not to Label…

Nothing makes packaging more attractive than an attractively designed label. If you want to perform at the POS, you have to stand out. And if you want to be particularly beautiful, you have to suffer – in terms of recyclability. Inks, adhesives and finishes have a negative impact on the quality of recycled materials.

So from a design-for-recycling perspective, the best label is no label at all. We venture a glimpse into a future without labels and visualize label-less alternatives with the help of artificial intelligence.

Does packaging have to be recyclable?

In short, yes. At the end of April 2024, the European Parliament approved the planned Packaging & Packaging Waste Regulation which standardizes the handling of packaging throughout the EU. The aim is to reduce waste and promote the use of recyclates, e.g. through the so-called minimum recyclate content for plastic packaging. The latter calls for mandatory minimum targets that increase in stages – including for food packaging. However, there is currently neither the necessary quality nor the quantity of recycled materials.

Only rPET (PET from the deposit system) currently meets the quality criteria required for meaningful reuse in food (more on PET here). Other plastics currently have neither the approval nor the necessary recycling systems to become “good” recyclate.

Ergo: everyone wants high-quality recyclates, but we have far too few of them.

Was hat das Label mit der Rezyklatqualität zu tun?

99% of the plastic packaging that makes it through the sorting plant ends up in mechanical recycling. In this process, the packaging is washed, shredded and processed into new granulates. The more “impurities” a packaging contains, i.e. additives, printing inks or components from other materials, the worse it is for the granulate.

Dr. Christian Kirchnawy from the Austrian Research Institute for Chemistry and Technology (OFI) is working on new methods for the safety assessment of food packaging to make it easier to evaluate unknown contaminants. Dr. Kirchnawy’s team is also investigating whether critical degradation products can be produced during the recycling of printed packaging. The research has not yet been completed. However, according to Dr. Kirchnawy, one thing is already clear: “Printing inks on labels are generally not desirable for recycling, both for optical and food law reasons.”

Avoiding contamination from printing inks is no easy task. One solution is the development of new chemical or biochemical recycling technologiesin which colors and impurities are better filtered. Another is the optimization of products for the existing mechanical process – for example by eliminating labels.

Printing inks containing mineral oil are also a major problem in paper recycling. Although they mostly enter the paper cycle from newspaper printing, they can also come from packaging. The use of waste paper in food packaging means that these harmful MOSH/MOAH components can get into the food itself.

How can you communicate without a label?

As a result, you might think that the best way forward is to do without pressure completely. But what can such a pressure-free product look like?

The big players are leading the way. From January to March 2024, the Coca-Cola Company tested Sprite bottles without a label on the British market. The product information was laser engraved directly into the body of the bottle and the Sprite logo was embossed over a large area. Their brand is still clearly recognizable thanks to the iconic lettering and the familiar bottle shape. The variety variations are communicated via the lid color. Factors such as legibility and accessibility naturally suffer in the print-free version. It has not yet been announced how the trial was received by consumers.

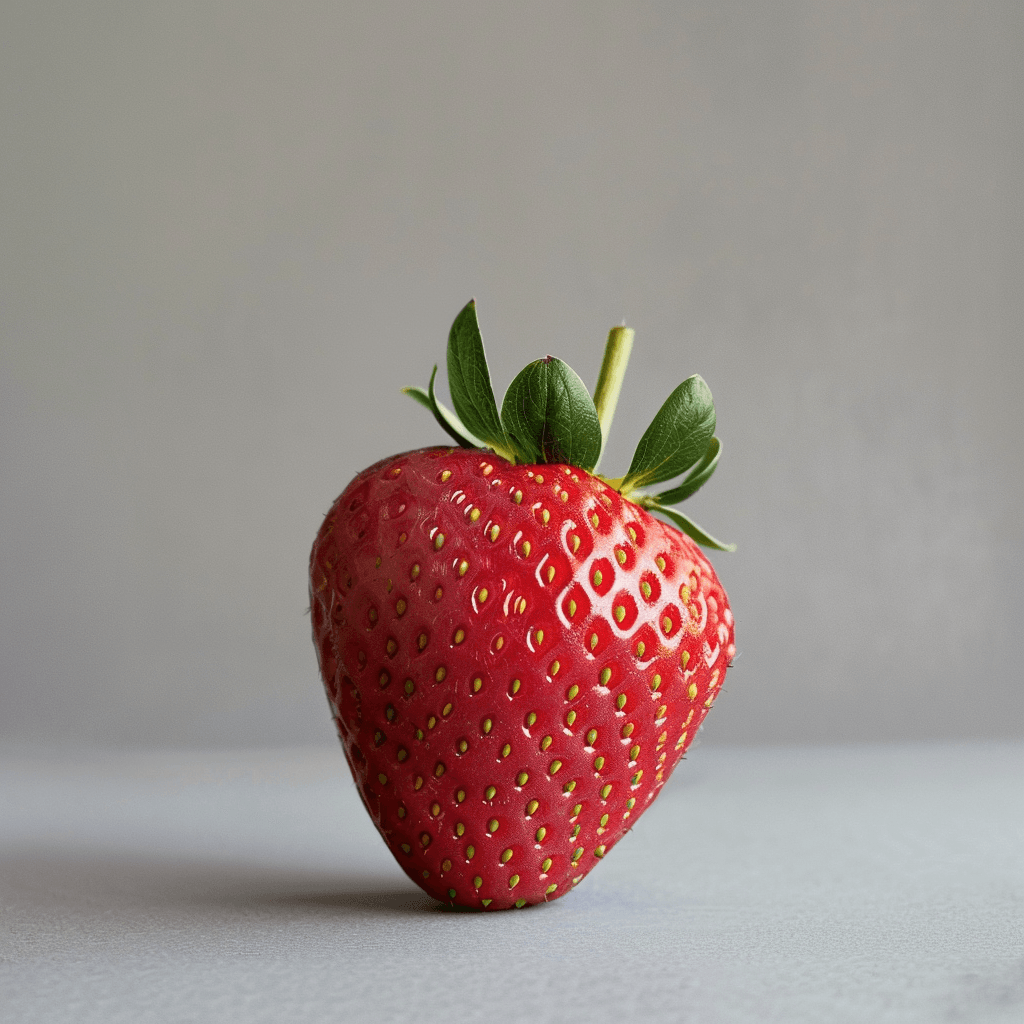

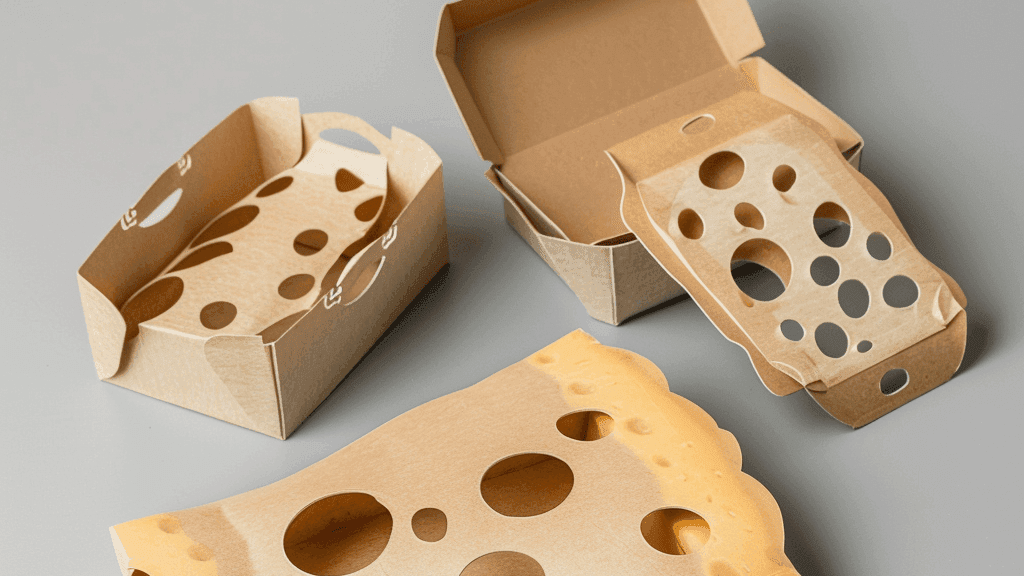

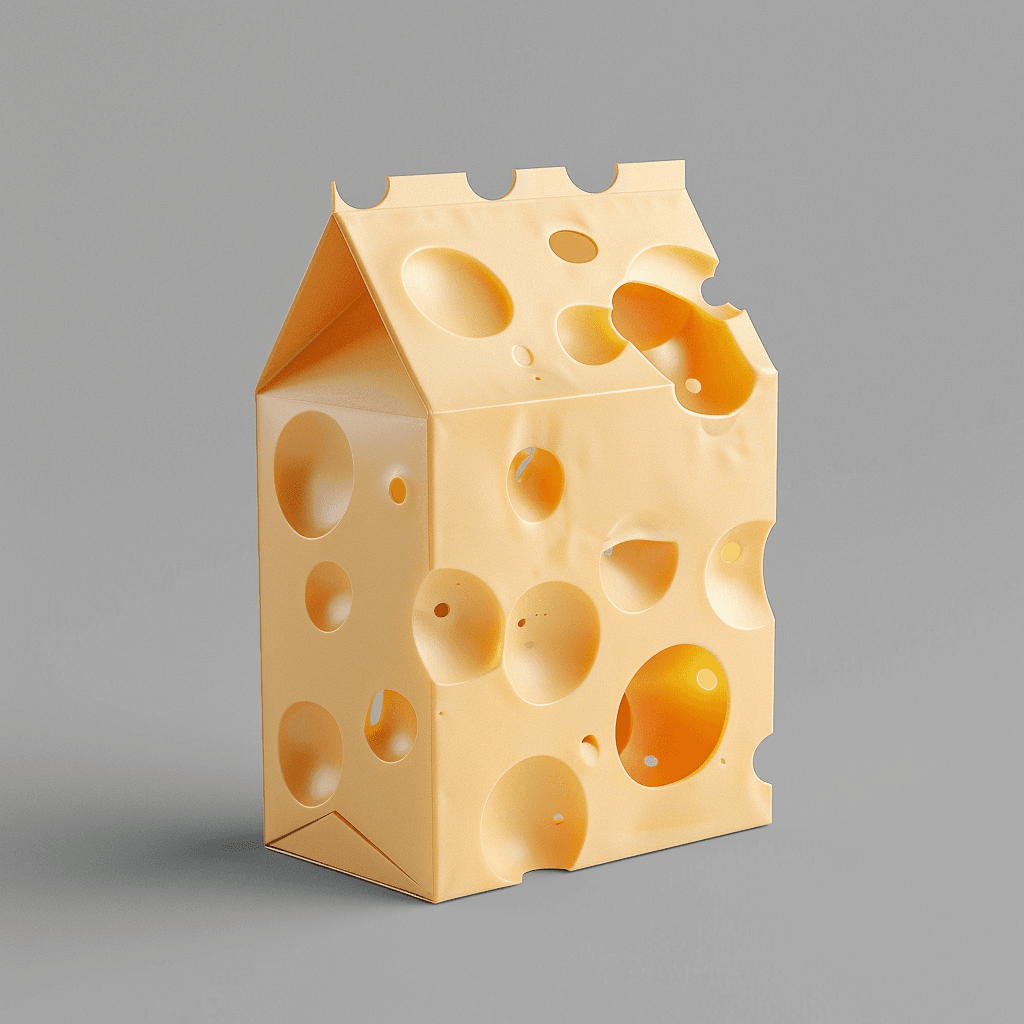

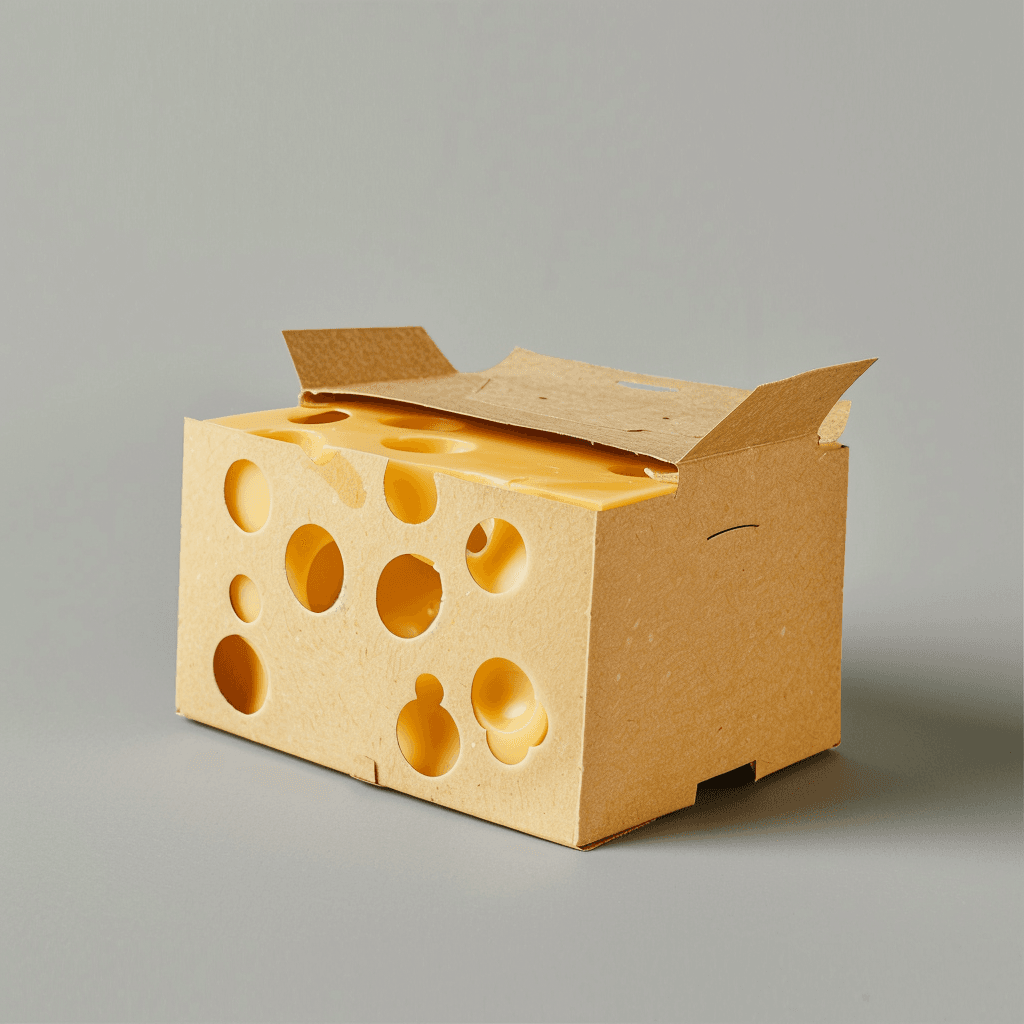

In our visualization experiment, we go one step further and completely dispense with words and writing. With the support of AI-based software, we are trying our hand at concepts that only communicate haptically and visually by picking up on typical product features. Whether fish scales on a can of sardines, hairy peach iced tea or cheese packaging with holes – the contents of a package can be reproduced using typical patterns and textures. You can not only see them, but also feel them.

What goes beyond the content is of course difficult to describe without words. Switching to a QR code could be a compromise solution, but one that consumers would not be happy about.

Conclusion:

A future without labels at all would be somewhat bleak. But rethinking them, integrating all the senses and communicating in a more refined and reduced way – that’s the label we’re going to put on ourselves.