Bioplastic Polystyrene

Mealworm Exoskeletons As Styrofoam

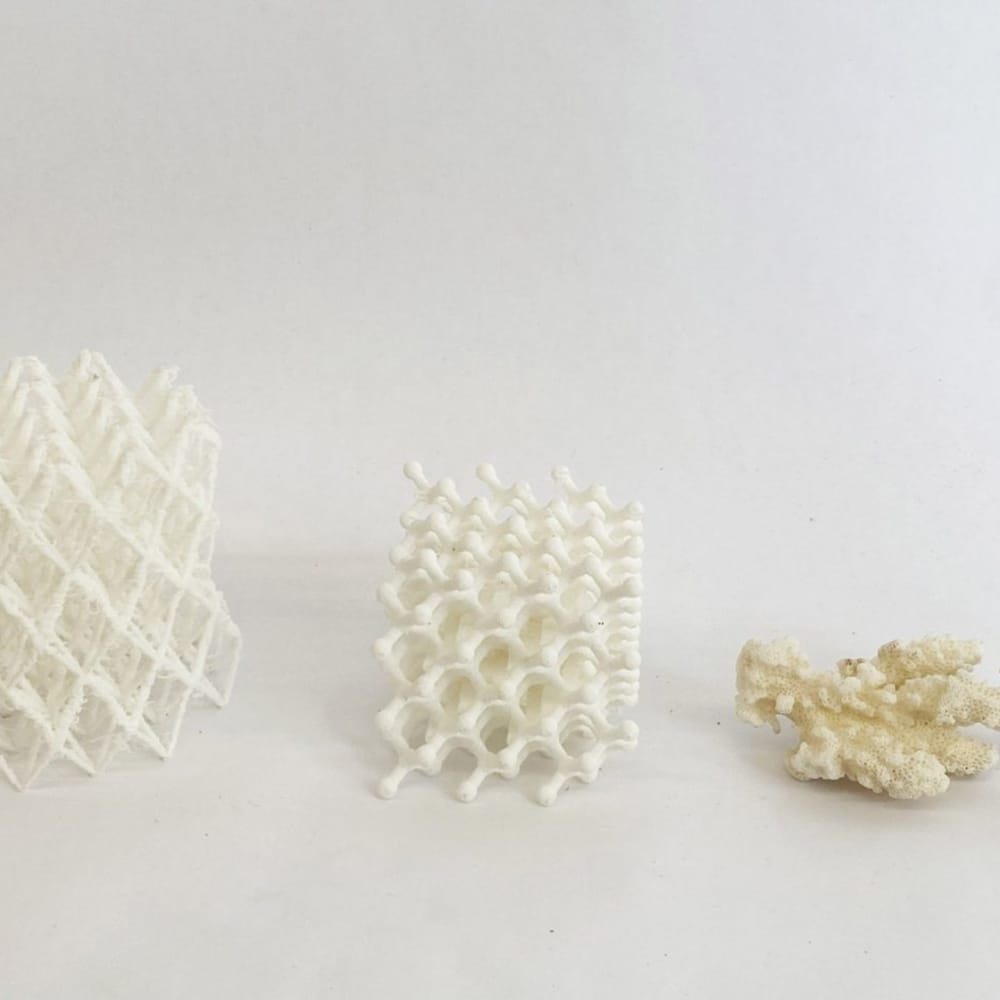

The designers and founders from studio Doppelgänger developed a polystyrene (EPS) alternative that is shock absorbent, water-resistant and is claimed to be home compostable. Charlotte Böhning and Mary Lempres developed their Chitofoam from the biopolymer chitin derived from mealworm exoskeletons. First, the mealworms are used to digest and break down waste polystyrene. Once the worms reach the end of their life cycle, the designers extract chitin from their exoskeletons by treating them with an alkaline solution in a process called deacetylation.

Chitofoam can be cast or injection-molded into desired shapes. Thanks to its thermoplastic properties, it can be melted down and reshaped into new products.

The process and formula is still patent pending while the designers are testing its thermal insulation properties for hot foods and beverages.

Product Name: Chitofoam

Manufacturer: Doppelgänger

Project Status: Concept // Prototype // Market Ready // Series Production Ready

Source: dezeen

Image source: Doppelgänger