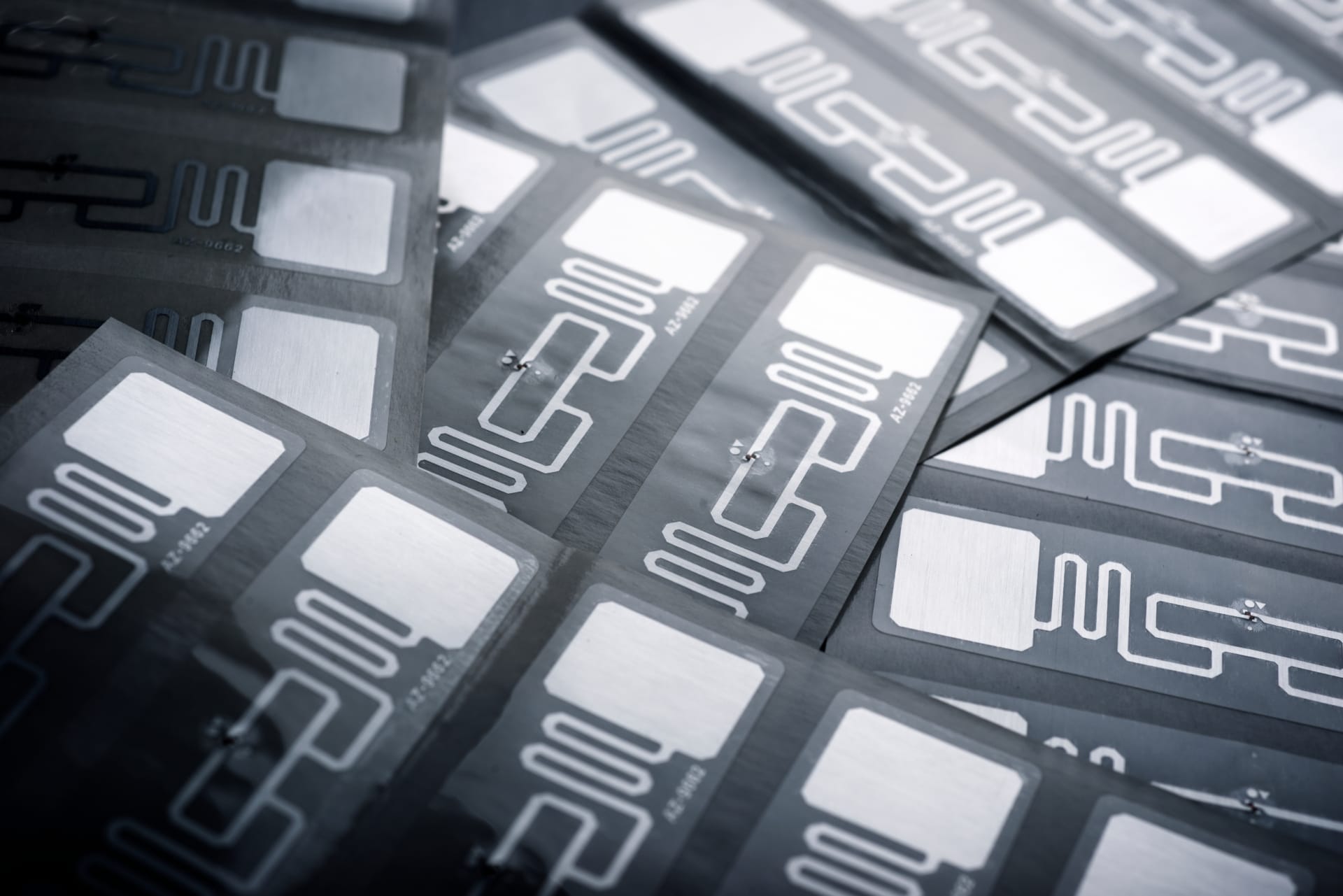

Small chip, big effect. Contactless identification of packaging.

Digitalization does not stop at the packaging industry. RFID tags (Radio Frequency Identification) are now widely used and have become increasingly important, especially in the context of logistics optimization. The wafer-thin chips, which are incorporated into the product, enable efficient management throughout the entire supply chain.

RFID transponders can be read without contact and have a range of 6 meters (passive transponders) or 10 meters (active responders), depending on the frequency range. The radio waves can also penetrate shelf walls or truck tarpaulins. This type of identification enables data to be recorded quickly and precisely, increasing efficiency in logistics. Compared to barcodes, a larger volume of data can be stored and data access is simplified through automation. They are mainly used for traceability and to track packaging. They are also used to support reusable systems, as our trend article on the subject shows.

Concerns about the system come primarily from the data protection corner.

But the recycling of packaging is also made more difficult by the integration of RFID chips – if they are not removed beforehand. However, as the chips have been on the market for several years now and experience has been gained with them, the problem can be solved by correct labeling, for example. There are now also new types of tags that are made from more recyclable materials. They use substrates made of paper or other materials, without silicone. This also makes the tags cheaper – the biggest obstacle so far has been the price.

Our conclusion: An established technology that has regained some relevance thanks to developments in the reusable sector. However, we see greater potential for “tomorrow” in digital watermarks such as Digimarc.