Sustainable from alternative natural fibers.

Image source: Creapaper

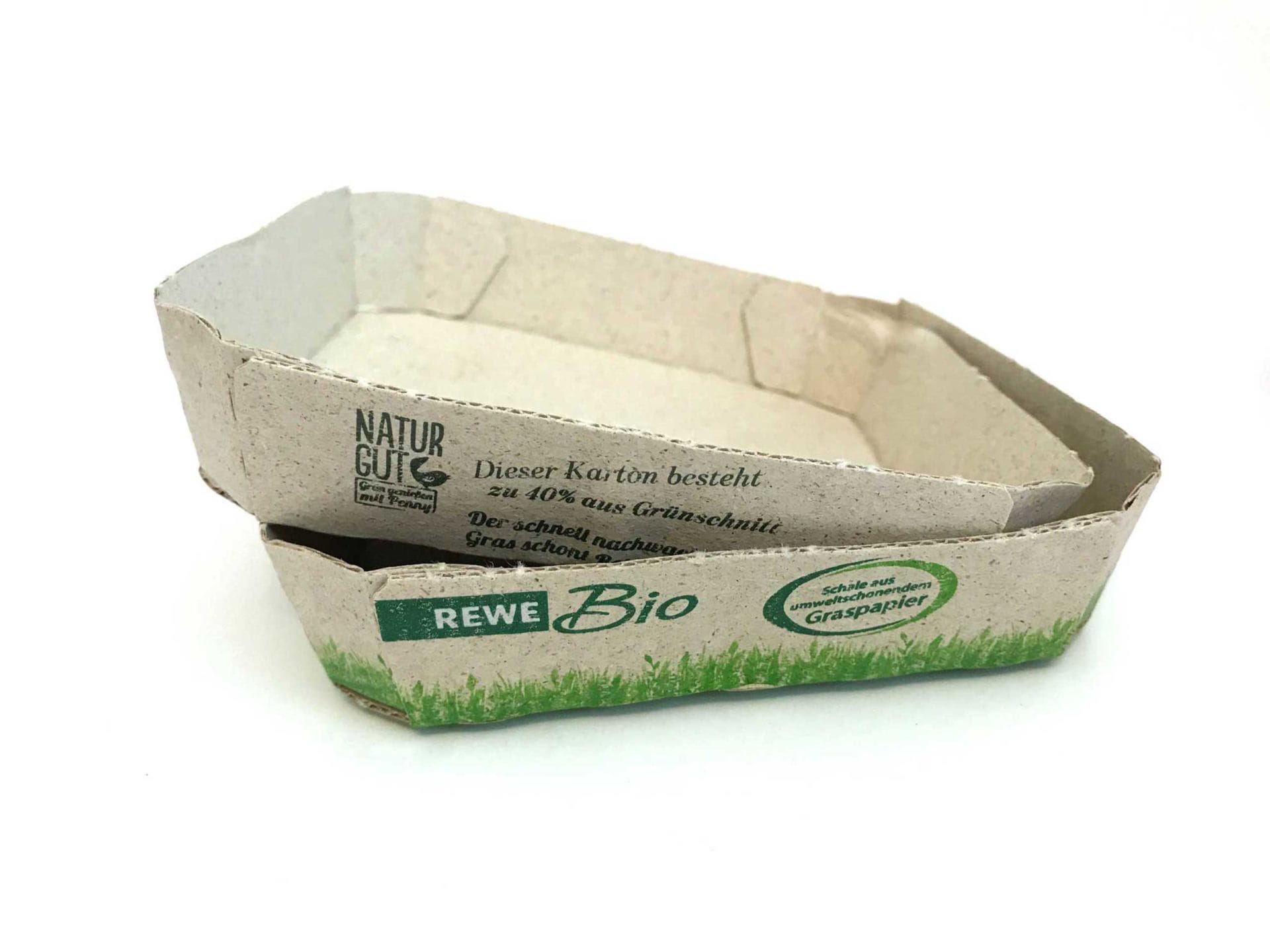

Grass papers such as those from GRASPAP® are purely mechanically, but particularly sustainably produced natural fibers. Compared to wood, they are usually processed without the use of chemical additives and with significantly less water. In addition to these ecological and economic aspects, the fiber is characterized by special properties for paper production: It serves as a supplementary raw material for pulp and has different fiber lengths with individual fines content and different fractionations. GRASPAP® is also characterized by improved CO2 values of up to 75 % and is suitable for the recycling loop.

Image source: OutNature

The Schwarz Group, among others, is pursuing a similar approach with the use of Silphie papers. This fast-growing composite plant is currently cultivated on around 10,000 hectares in Germany, requires little fertilizer and no pesticides from the second year of growth. Their fibers currently only work when mixed with pulp made from wood fibers, but the eco-balance is still impressive. As the scientists at Fraunhofer UMSICHT were able to determine in their study of papers from the manufacturer OutNature, silphie papers perform better than wood in many aspects of the life cycle assessment. As a result, the paper was also able to secure the German Design Award 2022 in the “Materials and Surfaces” category. The main disadvantage is the effect on the soil, as it is depleted during silphie production.

Both grass and silphie paper also have shorter fibers, so they are normally only recycled 3-4 times. A long wood fiber can be used up to 25 times.

We are particularly interested in this solution because of its suitability for use with food. The virgin fiber can remain untreated, recycled fibers require a MOSH/MOHA barrier against mineral oil migration.

Our conclusion: Grass and Silphie paper are a good supplement to conventional papers and can score points above all through regional cultivation and rapid raw material growth. Currently, the available tonnages are still limited and the costs are higher. The PPWR could lead to an upswing again.

Best practice: Graspap by Creapaper