The best of both worlds: Cardboard hybrids for plastic reduction.

Image source: SEALPAC

Less is more is the principle of the “Reduce” trend.

With hybrid packaging, attempts are being made to reduce the proportion of fossil materials in particular through smart material combinations.

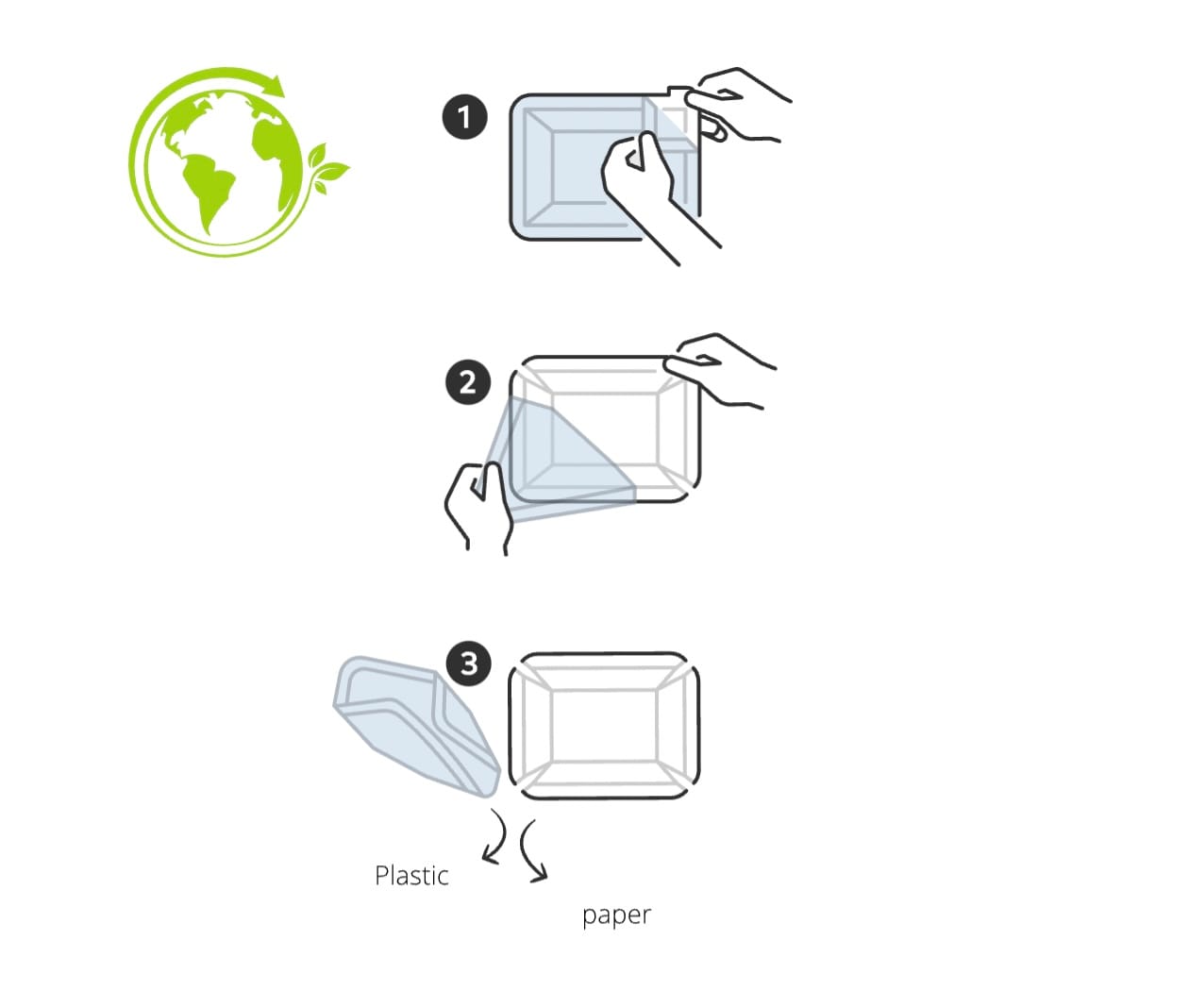

Such as the “eTray” from SEALPAC. This is a prefabricated cardboard tray in which the plastic or plastic composite used serves only as a sealing and functional medium. A cardboard blank is given a plastic inlay made of sealable PP in a thermoforming process. The blank is then erected and delivered as a prefabricated tray. After use, “eTray” can be very easily separated into its two main components, i.e. the functional material (plastic inlay) and the carrier material (cardboard or fiber material), resulting in significantly less waste, which can be disposed of separately by material. According to SEALPAC, around 40 to 60 percent of plastic is saved in relation to the conventional PP packaging format.

Image source: MILK.

We have already had the pleasure of working with this contemporary packaging solution for various customers. In the example shown above, the frozen products of Seubert Feinkostmanufaktur were packaged with a hybrid solution from Halopack. The thin plastic layer still provides optimum product protection, but is easy to remove and can therefore be disposed of in the yellow bag (in Germany). The amount of plastic compared to comparable plastic trays with top film can thus be significantly reduced once again. At the same time, consumers enjoy the aesthetics of carton packaging with its warmer, more natural feel. The cardboard part of the packaging later goes into the recycling loop for paper, which works well in Germany.

Image source: Halopack

Our conclusion: A very good approach that uses established material flows without compromising on product protection. The challenge remains that consumers are – as always – responsible for separating packaging correctly and disposing of it in the right garbage cans.